Thanks for all the feedback on my previous blog, it generated some really interesting viewpoints. I think it is fair to say that there are evangelists, agnostics and atheists surrounding the world of BIM.

The evangelists are clearly enthusiastic about promoting BIM to the construction world, and want to bring everyone into their utopian vision where everyone works together in collaboration towards a common aim, the Common Data Environment.

However, the reality is that the construction world is complex, and there are so manydifferent opinions that the manufacturing masses don’t know which one is best to believe in.

Unfortunately, the evangelists seem to have focussed on the big picture – Plan of Work, Maturity Levels, Data Drops, BEPs, PIPs all wrapped in abbreviations and acronyms.

The trouble here is that all this means very little to the manufacturer: there's a whole new language out there that most don’t understand and in most cases will never need to understand because they relate to how the project is delivered rather than the product.

For the manufacturer, BIM content can be simplified down to fundamental information:

- This is what my product looks like - Spatial Information

- This is what it does - Performance Data

- This is what it needs - Operation and Maintenance

Let’s have a look at the issues each of them present.

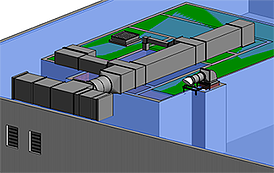

1) Spatial Information - How it looks, how big it is and how it fixes to the building

The best way currently to transfer this information is to draw it in either 2 or 3D. While the enthusiasts get all hot under the collar about the Common Data Environment not being tied to one software platform, the supposed one true church, Industry Foundation Class (IFC) doesn’t have enough disciples.

The reality: Revit is the content that suits most

My experience has been that by far the most common platform is Revit. The evangelists might want to tell you that Revit is not BIM, and that anything produced in Revit is only ‘Revit Content’, not ‘BIM Content’. The way I see it, Revit Content is a subset of BIM Content; even if it is not the content that suits everyone, it does appear to be the content that suits most. Until there is a common software platform that readily allows the export of Revit content at product/family level to other platforms then this issue will remain.

Third party content creation requires high investment

The trouble for many manufacturers is that the investment required to employ a 3rd party to create content is high. Estimates suggest a cost in the order of £2-3000 per product and with a product range of around 50 variations that level of investment is unlikely to happen without a clear ROI.

In-house content creation means Revit

So in the short-term, we have elected to develop our product content in-house and in Revit. The cost of investment and training in more than one platform is also prohibitive.

2) Performance Information. This is the parametric data that people often refer to

Within all the software platforms this is readily configurable. The only issue is the same as what we have with Spatial Information: making the information transferable between the various platforms. Clearly a spreadsheet based data environment is going to be most transferable.

The demand for COBie is not high enough to justify the investment

However, if the demand for BIM or Revit content is not high enough for manufacturers to engage, then the demand for COBie is even less like, because as things stand, only government contracts are likely to be interested in COBie and the number of private sector projects using 3D design environments without COBie seems to be drastically outstripping those that do.

3) Resource and Support Information – otherwise known as the Operation and Maintenance manual

This describes what resources the product needs to operate and how to keep it running or what to do if it stops running. For the building owner and the facilities management team, this is the prime mover, but from my own point of view, the least understood in terms of how this information is to be stored, retrieved and accessed over the life of the building.

What needs to happen for BIM to become mainstream?

I believe that there are several key issues that need to be resolve before BIM becomes mainstream in all of the sectors described above:

1) For manufacturers:

Embrace change, develop a plan of action and create parametric models for your primary product portfolio:

- Research and secure budget

- Agree software/format, product variants, structure and level of detail – aim for consistency

- Decide on whether to develop internally or outsource

- Manage/update product families as products get updated

- Place on website and push to your customers

- Consider a 3rd party hosting website for product sales

- Engage with your customers on the subject

- Don’t get hung up about IPR: the level of detail required for BIM content is up to you and there is plenty of opportunity for you to develop good quality content without compromising IP.

2) For the leaders

- Engage with manufacturers, be clear about what is required

- Be more insistent on content, but allow time to deliver

- Give feedback, it is supposed to be a more collaborative process

- Resolve the contractual concerns that are slowing down adoption

- Adopt a common naming convention across the industry.

3) And finally for the software suppliers

Two things:

-

Firstly, none of us want to go to the trouble and expense of developing our product content for it to get ripped off by our competitors or by our customers and replaced with another company name.Give the manufacturer some security and devise a way to ‘watermark’ our products.

-

Secondly, develop IFC so that information is transferable between software platforms at product level. One of the hurdles for manufacturers developing content is that they do not want to have to develop content over every software platform. A means of translating from one platform to another, without having to go back to basics, would ease the reluctance to engage considerably.

Conor Logan is a Technical Manager of Colt UK, Smoke and Climate Control Division. Conor designs innovative smoke control and HVAC systems and is also Chairman of the Smoke Control Association.

Conor Logan is a Technical Manager of Colt UK, Smoke and Climate Control Division. Conor designs innovative smoke control and HVAC systems and is also Chairman of the Smoke Control Association.