Mechanical shaft systems have plenty of advantages compared to a BRE Shaft or any natural system but they suffer from one major disadvantage compared to natural shaft systems.

Mechanical shaft systems have plenty of advantages compared to a BRE Shaft or any natural system but they suffer from one major disadvantage compared to natural shaft systems.

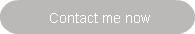

Why depressurisation can be an issue with with mechanical shaft systems

With natural systems, when the doors are closed there is effectively no flow of air through the system and the internal space is not depressurised.

By contrast, if a fan is installed at the top of the shaft, then that fan is going to keep running in such a way that even when doors are closed it is still going to be sucking away. If the lobby is closed, this is going to create a very high negative pressure. Negative pressures of -100 or -200 Pa. are easily achievable and in this situation it becomes very difficult for people to open doors and there is the risk that this will prevent people from escaping.

The solution to depressurisation with mechanical shaft systems

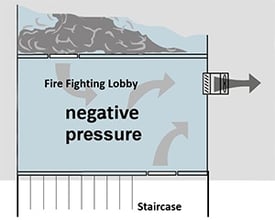

Various designs have been used over the years to deal with this problem. In our opinion the best solution is to use pressure sensors and variable speed fans, as with the ColtShaft Variable system. This system provides ventilation to match or exceed that provided by the BRE Shaft and also maintains fire compartmentation.

Colt’s system is LABC approved, thereby providing prior assurance of Building Control approval.

Schematic for ColtShaft Variable

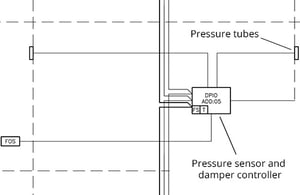

Schematic for ColtShaft VariableA second best alternative is to provide an inward opening door from the stair into the fire-fighting lobby so that the door can be pulled slightly open by the fan and a limited negative pressure can be maintained by the fans, as with the ColtShaft Constant system.Such a system uses a simple fixed speed fan, sized to provide the full ventilation rate when the stair door is open.

Schematic for ColtShaft Constant

Schematic for ColtShaft ConstantComparison of the above approaches

In the meantime this table gives a brief comparison between the two approaches.

| Feature or issue | ColtShaft Constant | ColtShaft Variable |

| Fire compartmentation | Fire compartmentation broken by action of door opening when system in operation | Fire compartmentation maintained as designed |

| Direction of escape | Door to stair opens inwards away from direction of escape | Door to stair opens into stair in direction of escape |

| Pressure relief | Stair door relieves lobby pressure by opening into lobby | Pressure sensor controls fan speed in closed control loop by inverter |

| Door does not open due to blocking, damage or wear | Pressure builds up in lobby and door opening forces rise above 100N with high risk of trapping occupants | No effect |

| Pressure sensor fails | No effect | Shaft runs at 5% providing limited protection to stair. Fire-fighters’ override switches off pressure sensor and system runs at full speed |

| Colt door closer replaced with standard closer | Door fails to open as designed and lobby pressure is not correctly controlled | No effect |

| Accommodation door to fire source left open as closer removed or damaged | Door closes smoke extracted | Shaft system ramps up to full speed and aids smoke clearance |

| Inverter fails in fire condition | No effect | Possible failure mode has been proposed. Unlikely event, no known recorded instances in the field. Fire-fighters can switch off inverter |

| Building leakage at first build and subsequent variation | Calibration, setup and effectiveness changes with leakage | Self-optimises via closed loop control. Building leakage can be between 5% and 40% of fan duty |

In the final analysis, whilst the ColtShaft Constant system is simpler and less expensive, its operation relies on door closers being maintained in top condition.

Webinar - Smoke and environmental ventilation of multi-storey buildings using shafts

17 July 2015, 12.30-13.30 BST

This CPD-accredited webinar looks at the various types and applications of shafts. Accompanying the webinar will be a whitepaper summarising the key points.

The webinar will cover the prevailing legislation and guidelines for various types of buildings, including:

1) Prescriptive staircase requirements for fire-fighting and means of escape in residential buildings

2) Ventilation of common corridors in residential buildings

3) Extended travel distances in common corridors using mechanical shafts.

We will also touch on the options to make use of smoke control systems to provide day to day ventilation to reduce temperatures in corridors in residential buildings, including using active cooling.

The webinar is CPD-certified, which means that by completing it you will be able to claim CPD points.

There will be the chance to ask me questions at the end of the session, and for those who register but can't make the webinar at the last minute, the session will be recorded and made available online.

Whitepaper - Smoke and environmental ventilation of multi-storey buildings using shafts

Download the whitepaper which looks at the various types and applications of shafts.

Paul Compton is Technical Director for Colt, experienced in smoke control, HVAC, solar shading and louvre systems.

Paul Compton is Technical Director for Colt, experienced in smoke control, HVAC, solar shading and louvre systems.