Air filters are used in heating, ventilating and air conditioning (HVAC) systems to improve air quality in indoor working environments. They can also serve to protect the HVAC equipment.

Air filters are used in heating, ventilating and air conditioning (HVAC) systems to improve air quality in indoor working environments. They can also serve to protect the HVAC equipment.

Pollutants can originate from a source outside or inside the building. In this blog post, I will discuss pollutants which originate outside of the building.

So how fresh is 'fresh-air'? The answer is - it depends. It depends on your location and the prevailing outside conditions at any given moment. Filtration can be used to combat the uncertainty of the outside air conditions.

By the end of this post, you’ll:

- Have a better understanding of HVAC filter classification

- Be able to determine which grade filter you need

- Know where to get various grades of filtration depending on your needs

How are the filters graded: HVAC filter classification

In this section, I will explain the old and new system of how air filters are graded and classified.

Air filters are available in a variety of grades depending on the particle size you want to filter out.

The old standard for testing and classifying HVAC air filters

Prior to June 2018, BS EN 779:2012 provided a method for checking the performance of air filters provided in general ventilation systems.

BS EN 779 Filters

Filters were ranked according to their particulate removal capability and given a classification accordingly. The standard specified three filter groups: G (coarse), M (medium) and F (fine).

- Coarse filters were classified according to the average arrestance of synthetic dust used in the test. They ranged from G1 (50-65% arrestance) to G4 (90% arrestance).

A coarse G4 filter is designed to capture pollen, fog and coarse dust particles (≥10μm). It also captures leaves, insects, textile fibres, sand, ash, mist and hair. (Note: 10µm is 0.01mm.)

- Medium filters were classified according to the average efficiency (Em) of 0.4μm particles. 0.4μm and larger particles include mould & plant spores, pet dander, textile dust, skin flakes, yeast cells, insecticide dust and most bacteria.

There are two classifications for medium filters; M4 (40% ≤ Em < 60%) and M5 (60% ≤ Em <

80%).

- Fine filters were also classified according to the average efficiency (Em) of 0.4μm particles. however, these filters also have to meet a minimum efficiency level.

Classifications range from F7 (80% ≤ Em < 90% and a minimum efficiency of 35%) to F9 (95% ≤ Em and a minimum efficiency of 70%).

The minimum efficiency is the lowest % value during the complete installation cycle of the filter. The average efficiency is the average % value during the three stages of the filter installation cycle:

- Initial efficiency

- Efficiency throughout the test’s loading procedure

- Efficiency after discharging

BS EN 779:2012 also sets of maximum final test pressure drops to promote energy efficiency. For coarse (G) filters it's 450Pa. For medium (M) and fine (F) filters it's 450Pa, at the specified test volume of 0.944m³/s.

It is important that filtration has been tested to BS EN 779:2012. This ensures that filters have had a demanding check of their quality and performance.

The current standard for testing and classifying HVAC air filters

The new standard, ISO 16890, was developed in response to the new knowledge we have acquired about air quality over the years.

What was wrong with EN 779? One of the main limitations was the fact that EN 779 tested a filter's performance against one particle size - 0.4 µm. However, particulate matter is not uniform in shape or size. Therefore, exposing a filter to one particle size in testing is not reflective of the conditions it will face in reality.

The new ISO 16890 standard focusses on a filter’s ability to capture particles in the danger zone (where particles are too small for our bodies to protect against).

Testing under ISO16890 exposes filters to particles ranging in size from 0.3 µm to 10 µm. This more accurately represents the air that the filter will operate in.

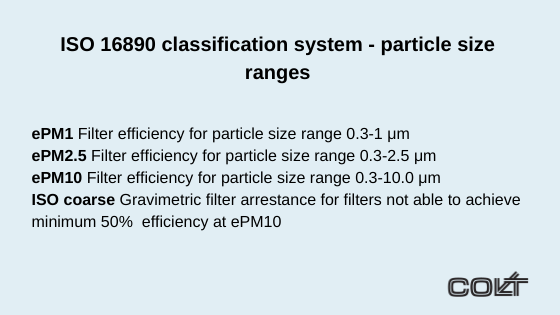

The ISO 16890 classification system: air filter grades explained

With the new system, air filters are classified based on their efficiency at:

- PM10

- PM2.5

- PM1

- ISO Coarse

(PM means particulate matter with a diameter less than 10 µm, 2.5 µm and 1 µm respectively).

(Notes: ‘e’ is the removal efficiency in the particle size range between 50 – 99% removal; filters with removal efficiencies above 99% are tested to the ISO29463 range of standards.)

Which HVAC filter grades do you need?

To reiterate what was said earlier: filtration can be used to combat the uncertainty of the outside air conditions.

In some industries, it is essential to ensure that the internal climate meets the exacting demands for production. The food industry for example, where F9 filters would be vital to maintain the required levels of hygiene and product quality. But where the process is less sensitive it may only be a consideration to improve the working environment for building occupants.

Colt can offer grades of filtration depending on your requirements.

Laurence Cockman is a Senior Consultant for Colt UK and specialises in the design and product application of energy efficient HVAC systems.

Laurence Cockman is a Senior Consultant for Colt UK and specialises in the design and product application of energy efficient HVAC systems.