Power generation plants are complex building installations. When designing a ventilation scheme for this type of facility, the necessary calculations can’t be done on the basis of drawings alone. You need the right expertise in climate control and the right tools – a Computational Fluid Dynamics (CFD) analysis carried out by an expert is the best answer.

A powerful tool for a complex problem

Every building’s internal climate is affected by various factors, such as location, orientation, the materials used in its construction and its function. It interacts with the environment, so that seasonal changes in weather conditions and temperature also have an effect.

Power plants have to deal with additional factors, such as excess heat and humidity, contaminants resulting from the power generation process and, in the case of energy-from-waste facilities, odour. This type of facility also has a complex structure, making it more difficult to calculate the way air will flow within the building.

A good ventilation design can mitigate all these factors, so that the power generation plant can operate at maximum efficiency at all times. CFD analysis, applied with the right expertise, is the ideal way to map out how these numerous factors interact within the building structure and how to achieve ideal conditions in every part of the facility.

High precision predictive models

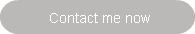

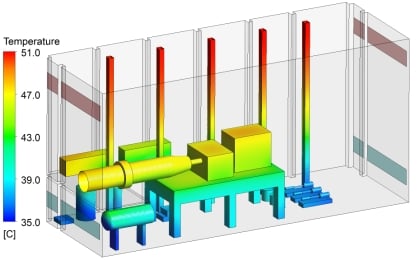

With a good CFD model you can make extremely reliable predictions about the internal environment without having to test a scale model in a wind tunnel. The CFD expert can create a 3D model consisting of thousands or millions of volumetric elements. With this tool, he can analyse mass flows, heat transfer and associated phenomena to quantify the expected effects on temperatures, air speeds, emissions and pressures. The CFD simulation will also flag unexpected effects and enable the expert to devise solutions to address and optimise them.

With CFD modelling, you can also implement “what if” scenarios, so that you know how the facility will react in different situations and make sure your design addresses the possible issues effectively.

Graeme Clark is a Senior Consultant for Colt UK and specialises in the design and product application of energy efficient HVAC and smoke control systems.

Graeme Clark is a Senior Consultant for Colt UK and specialises in the design and product application of energy efficient HVAC and smoke control systems.