In the vast majority of cases, natural ventilation is the most effective and economic solution for factories housing production processes generating high levels of heat:

In the vast majority of cases, natural ventilation is the most effective and economic solution for factories housing production processes generating high levels of heat:

• Natural ventilation is best suited to buildings where a large amount of internal heat is generated, since this leads to a high temperature gradient.

• If the building is tall, then this provides even more ideal conditions for natural ventilation to work at its most efficient, since this creates a good stack effect that makes moving air between different levels within the building easier.

The ventilation system must guarantee that the maximum temperatures that allow the efficient operation of the plant as well as comfortable working conditions for the staff are never exceeded.

Natural versus mechanical ventilation

As a designer, whether it is a new building that will have high internal heat gains or a retrofit to an existing building, you will be evaluating the respective benefits and feasibility of natural and mechanical ventilation.

You will also looking for a solution that is cost effective, and with natural ventilation running costs are negligible:

• No energy consumption

• Minimal maintenance

• Self-compensating: the hotter the air, the more air can be moved and the more efficient the system is

• Long life span

• Not liable to breakdown.

However, in some cases, natural ventilation won’t be possible:

• When the building doesn’t provide enough height to achieve a good stack effect

• When there isn’t sufficient internal gain to generate temperature gradient

• When there isn’t enough space at low level to provide for the required inlet area: with natural ventilation, the pressure differential across the inlet or extract system must not be too high, or it won’t work effectively

• When the building is entirely or partially enclosed within a main structure, so that there is no direct access to the outside and therefore it is impossible to provide openings for natural ventilation.

Choosing the right solution

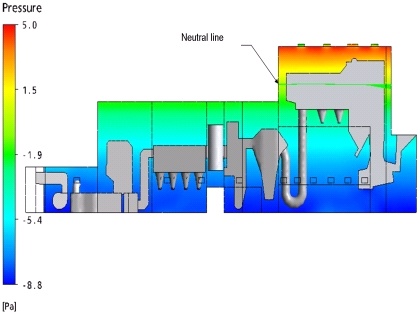

Computational Fluid Dynamics (CFD) analysis, carried out by an expert in CFD simulation, is an excellent tool to identify the best system for each building. These simulations can show the flows and transfer of energy within the building in different situations, helping to develop the most effective solution.

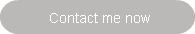

In our example of a building with areas of different heights open to each other, the CFD simulation shows that the neutral plane is in the top section of the building. This means that the natural exhaust ventilation system is only effective above this line, while air inlets are spread at low level across all areas.

The CFD simulation of air movement and velocity within the building indicates the best locations for inlet and extract ventilators.

In this building the CFD analysis shows how effective natural ventilation is and gives important information to design a well engineered system.

If you need help with your ventilation system design or CFD analysis support, you can contact us for a free consultation.

Graeme Clark is a Senior Consultant for Colt UK and specialises in the design and product application of energy efficient HVAC and smoke control systems.

Graeme Clark is a Senior Consultant for Colt UK and specialises in the design and product application of energy efficient HVAC and smoke control systems.