Evaporative cooling or ‘adiabatic cooling’ is a mouthful, we know. That’s why a lot of building owners and operators still don’t know about the effectiveness of these systems or the cost and environmental benefits they can deliver.

Evaporative cooling or ‘adiabatic cooling’ is a mouthful, we know. That’s why a lot of building owners and operators still don’t know about the effectiveness of these systems or the cost and environmental benefits they can deliver.

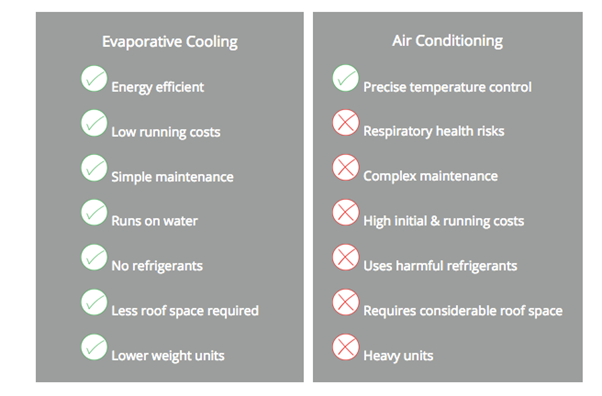

Many people don’t realise that if you manage a large industrial or semi-industrial facility where pinpoint control of temperature isn’t crucial, evaporative cooling can actually be a more effective choice than traditional air conditioning. Just have a look at the pros and cons associated with the different system types below – not only is evaporative cooling cheaper and more efficient, it introduces fresh air from outside avoiding poor health issues often associated with traditional systems.

Read on to find out what evaporative coolers are and why they could be better for your business than a traditional air conditioning system.

How does evaporative cooling work?

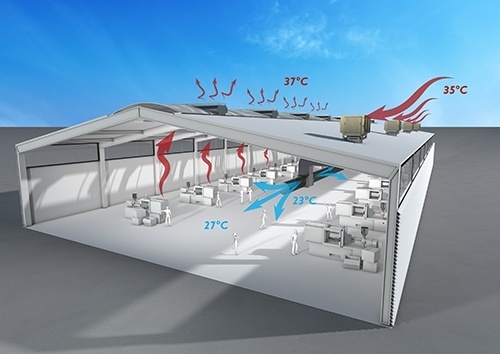

Evaporative coolers cool external air through water evaporation. It works via a two-step process, as outlined below. Prior to being cooled through evaporation, the outside air is initially hot and relatively dry, and so the air has a high proportion of (shown in red) so-called "sensible heat".

The primary cooling process for evaporative coolers.

As the airflow from the incoming air passes over the water, it evaporates into the air. The heat energy necessary for the evaporation is withdrawn from the air. The sensible air temperature decreases continuously through the evaporative cooling process. The evaporated humidity absorbed by the air is also referred to as "latent heat". Since the total energy of the air-water system remains the same with this exchange of sensible heat to latent heat, this type of evaporation is called "adiabatic" (taken from the Greek term for a change of state without the direct addition or removal of heat).

The secondary cooling process

As the evaporative cooling process cools down the air, the secondary phase is to remove the latent heat from the building. The temperature in the building falls as a result of the heat dissipation in the desired manner.

In the case of CoolStream, (Colt's range of evaporative cooling systems), direct evaporative cooling is in use. A special material is used to transport the water with many small channels through which flows the warm and relatively dry outdoor air. When passing through this wet medium the warm air is cooled considerably by the removal of sensible heat and this can then be used to cool down the building more effectively than air conditioning.

The air temperature passing through can be lowered by up to 15°C in Europe. In general, the hotter and drier the air, the more efficient evaporative cooling is.

Cooling that is good for the environment and cost effective.

Power-saving cooling systems

Colt's CoolStream range of evaporative cooling systems are up to seven times more efficient than conventional air conditioning systems.

In one hour, CoolStream S.T.A.R evaporative cooling systems consume only around 1 kW of electrical energy and 50 litres of water per 3m³/s of supplied hot air, providing up to 30 kW of cooling, depending on the configuration chosen. How is this achieved?

The EC fans that CoolStream systems use are inherently highly efficient. They operate at low power so they do not add heat to the airflow.

The system’s infinitely variable speed controls ensure that each unit operates using the least amount of electricity possible, ramping up and down only as required. As a result of them responding to demand, a reduction in energy use of up to 50% can be achieved.

Light on maintenance

CoolStream systems are reliable as they use proven, non-complex technology, which means that little maintenance is needed, saving you money in the long run.

Light on the environment

CoolStream systems run on water only and require no chlorofluorocarbons (CFCs) or similar refrigerants that are harmful to the environment. As a result they have no F-gas compliance issues. CoolStream’s inherent design automatically minimises water consumption. Depending on operating conditions, our evaporative cooling systems consume only around 50 litres of water per hour.

Safety-conscious cooling

CoolStream systems have been extensively tested and are in compliance with VDI 6022 (“Hygienic Requirements for Ventilation Systems and Units for Internal Spaces”). This is a holistic and rigorous standard for air conditioning systems and confirms the high quality of supply air.

Find out more about why CoolStream systems are so safe.

Commit to lower costs with evaporative coolers

Colt offers a full design and installation service, as well as commissioning, training and servicing to ensure that your system is running safely and effectively. Talk to our experts today about our CoolStream S.T.A.R range.

If your building is too hot or too cold, if your process gives off fume or moisture, if your product requires specific conditions during its manufacture or storage, or if noise is a concern, then we may be able to help you.

We can survey your building using a range of techniques and equipment to identify your problem. Once established, we can then recommend a solution based on proven design work.

Request a no obligation consultation with one of our technical experts

Paul Langford is an Engineering Director with experience in product development, manufacturing and testing for HVAC, solar shading, louvre systems and smoke control applications.

Paul Langford is an Engineering Director with experience in product development, manufacturing and testing for HVAC, solar shading, louvre systems and smoke control applications.