Power generation plants and energy from waste facilities, whatever their size, present several design challenges in relation to ventilation and smoke extraction.

Power generation plants and energy from waste facilities, whatever their size, present several design challenges in relation to ventilation and smoke extraction.

With over 85 years in ventilation and smoke control design, manufacture and install, Colt has worked with numerous power generation and energy from waste facilities. To help us navigate the challenges presented by these complex projects, one of the key tools we use to assist with designing effective systems in power generation, is in-house computational fluid dynamics (CFD). Before we explain the benefits of CFD further, let’s take a look at some of the most common problems a designer working on a power generation project might encounter.

Key considerations and challenges for ventilation and smoke extract in power generation facilities:

- Excessive temperatures. The plant typically has minimum and maximum operating temperatures for optimum plant efficiency and to ensure comfortable working conditions for its staff.

- Poor indoor quality as a result of dust and other irritants, particles and fumes in the air.

- Excessive condensation.

- The need to ventilate the building in all weather conditions.

- The building may be under negative pressure through lack of inlet air, which may reduce the efficiency of the ventilation systems.

- Depending on the type of facility, there may be higher than average risk of fire and/or explosions.

- High noise breakout through ventilators which can affect the local community and environment.

- Odour and fume control considerations

- The need to effectively evacuate smoke if an explosion or fire occurs.

As you can see, there are a multitude of different issues that need to be considered and natural and mechanical systems will have to be meticulously planned and work together seamlessly to achieve the ideal working conditions for both man and machine. This is where CFD comes in.

Using CFD Simulations to develop optimum solutions in power plants

Our Colt experts use advanced computational fluid dynamics simulations to develop the best smoke control and ventilation systems to achieve the ideal conditions.

Our Colt experts use advanced computational fluid dynamics simulations to develop the best smoke control and ventilation systems to achieve the ideal conditions.

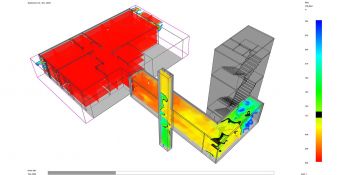

The CFD tool enables designers to predict flows and transfer of energy within a specific building in different situations. When working with an existing building, it can be loaded with the data resulting from thermal imaging, which identifies sources of heat in order to create simulations of air flows and heat transfer. This enables us to develop solutions to reduce excessive heat.

CFD’s main benefit is that it allows the designer to make extremely reliable predictions about the internal environment without needing to test a scale model in a wind tunnel. A 3D model of the relevant building is created for this purpose, consisting of thousands and sometimes even millions of volumetric elements. This model can then be used to calculate and graphically represent the results of the calculations, which can include air speeds, temperatures, air pressures and concentrations of pollutants. A building or process is visually examined from all perspectives using a model of the environment.

After commissioning the system, the CFD results can be validated with a site survey to check temperatures, noise, airflow, air pressure and air quality.

While CFD will help to ensure the design of a suitable and efficient system, the input requirements to create useable CFD models is very demanding and requires high-level expertise. If you are currently working on a complex project that could benefit from CFD modelling, talk to one of our Colt system design experts.

Additionally, Colt’s combined expertise and wide product and service range that includes not only smoke control, but climate control products and post-install maintenance too can help streamline all the stages of your project – we can help you integrate smoke ventilation units into the natural ventilation systems, saving you management time and money.

For more information on our smoke control product range, click here.

To view our climate control and ventilation solutions, click here.

Conor Logan is Associate Technical Director of Colt UK, Smoke and Climate Control Division. Conor designs innovative smoke control and HVAC systems and was Chairman of the Smoke Control Association for over 9 years.

Conor Logan is Associate Technical Director of Colt UK, Smoke and Climate Control Division. Conor designs innovative smoke control and HVAC systems and was Chairman of the Smoke Control Association for over 9 years.