If you read our blogs regularly, you will know that we recently asked our design team to help us answer some of our customers’ most frequently asked questions on smoke control. In Part 1, we covered four topics: car park ventilation, natural vs. mechanical ventilation, smoke dampers and environmental ventilation. If you missed that instalment, read it here.

In Part 2, we will be answering questions on CFD (Computational Fluid Dynamics), the components of a smoke control system, when you need smoke control in a building and pressurization systems.

Computational Fluid Dynamics (CFD)

What is CFD?

What is CFD?

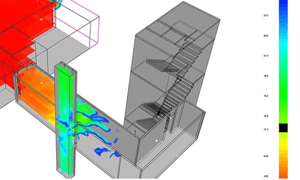

CFD (or Computational Fluid Dynamics) is a computer simulation process that predicts the movement of energy, momentum, fluids (air in our case) and species (smoke particles and gasses) for a given set of geometry limitations and boundary conditions in order to determine what would happen in certain scenarios. For smoke control system design, we use CFD to simulate various conditions and situations to determine if a system will be effective and robust at protecting means of escape and providing firefighter access. It not only helps designers make the right choices, but also gives peace of mind to any key stakeholders involved in the project that the system they are installing is fit for purpose.

What do you include in a CFD model and what do you get out of it?

Typically, we tend to model what is considered to be the worst-case scenario. For example, in a residential building, we might simulate a fire occurring in an apartment with a door that is located directly opposite the escape stairs – making it highly likely that smoke would enter. The results that we get from the modelling could indicate that the system is effective (or not effective) at stopping smoke from entering the stair. Alternatively, the tests might show that the system can clear the corridor of smoke in a certain amount of time, demonstrating that it does or does not meet the performance standards and specifications that have been prescribed.

Likewise, we may also run a similar model for the apartment furthest from the staircase to investigate the ability of the smoke control system to clear smoke from a long corridor.

What are the most important things to consider with CFD modelling?

The first key thing to appreciate is that due to the complexity of the calculations, it can take a long time to produce a CFD model, even with the most powerful of computers. Typically, we tell our customers to expect an output within 6 – 10 weeks. The second thing is that because it takes so long to achieve an outcome, you need to ensure that firstly, you have the right information from the outset, and secondly, you have a competent and experienced individual inputting all the information. The more detail goes into the model at the start, the more accurate the end results will be – if you start off with the wrong information, the conclusions drawn will not be valid. This is why it is also important to get full agreement from all relevant parties on the project parameters before you start the modelling.

The components of a smoke control system

What are the key components of a smoke control system?

What are the key components of a smoke control system?

In a natural shaft smoke ventilation system for a multi-storey building such as an office or apartments, you would have a lobby ventilator comprising a smoke control damper installed at every level inside the smoke shaft. The damper on the fire floor will open when a smoke detector or fire alarm is activated in the corridor or lobby (the area being protected) - the dampers on all other floors should remain closed. To protect escape stairs, a natural system would also have an AOV (Automatic Opening Vent) at the top of the staircase, which would also open when there is a fire to allow smoke ventilation.

For projects where natural ventilation is not suitable, mechanical fan sets can be installed. There are some advantages with these, as you can reduce the shaft size, which frees up more sellable or useable space within the building. These systems are not prescribed, so performance should be verified using CFD.

How do you know what size to make the different components of a smoke control system?

Designers will size up components based on data from the building. Important things to consider are whether the building has sprinklers, what the door heights are and the floor plan. Based upon this information, we can start building a CFD model to determine the appropriate volume flow rate that the fans would need to operate at.

It is important to get the sizing of the fans correct. If the fan is under sized, it could result in the system not performing to the right certification and specification. Conversely, over-sizing the fan could cause issues with doors being pulled open inadvertently or others being too difficult to open for escaping occupants. Oversized fans will have a larger starting current and a bigger control panel that will take up more space. In many instances, over-sizing could cause more issues than under sizing.

When do you need smoke control in a building?

There are numerous building types that need smoke control of one form or another:

- Any building with a firefighting core will need smoke control to the firefighting stair and lobbies – usually these will be buildings that are taller than 18m or if it has a basement that is deeper than 10m or more than one basement level with a floor area greater than 900m2.

- Multi-storey, multi occupancy residential buildings may require smoke control to stairs, corridors and lobbies.

- Shopping centres require smoke control systems.

- Theatres require smoke ventilators to the stage area and a safety curtain to keep it separate from the auditorium.

- Covered or underground car parks may be required to have smoke and fume clearance systems and in some instances a smoke control system to provide additional level of protection.

- Basements in excess of 200m2 may need a smoke clearance system to permit firefighters to get rid of smoke after a fire has occurred.

- Atria, particularly those that breach a building's compartmentation should be provided with smoke control.

- Any building where the fire strategy is using smoke control to compensate for a departure for the expected fire safety requirements - for example, a large warehouse or factory may be fitted with smoke ventilation in order to compensate for extended travel distances.

If you need to learn more about a specific building type’s requirements, talk to us.

What are the requirements for smoke control in residential buildings?

For residential buildings, the smoke control requirements will be dictated by the height of the building, the length of the corridors and the number of stairs. The recommendations are changing following Grenfell and BS 9991, the Code of Practice for Residential Buildings is currently being updated. More detail will follow in later blogs as the standard reaches publication.

What other types of buildings have specific requirements for smoke control?

The key building types (or design features within buildings) that have specific smoke control requirements are basements, warehouses and buildings with atria. If you need to learn more about a specific building type’s requirements, talk to us.

Pressurisation Systems

What is a pressurisation system?

What is a pressurisation system?

Pressurisation systems supply clear air to a protected space in order to increase the pressure in that space – this additional pressure prevent smoke from entering the area. For a more detailed explanation of how a pressurisation system works, read more about it in this blog.

When do you need a pressurisation system?

In the UK, pressurisation systems are commonly used when the traditional natural or mechanical smoke ventilation solutions are not suitable or compliant. It may also be used as an alternative to discounting a staircase when planning and sizing evacuation routes.

The latest draft of BS 9991 is also recommending pressurisation for single stair residential buildings over 18m, but this is only in draft format at the moment and may be subject to change.

What are the requirements of a pressurisation system?

The main requirements for pressurisation systems in England can be found in BS EN 12101-6: 2005 (soon to be replaced by BS EN 12101-6 & 13: 2022). These standards explain how to design a pressurisation system for all types of building - there are 3 key requirements that need to be met:

- The correct pressure in the stair core when the doors are closed

- The correct air velocity across certain doors when they are open

- A maximum door opening force must not be exceeded

The key things to keep in mind when designing a pressurisation system to meet all the requirements are:

- How will the pressurisation supply air get in and how will it be kept smoke free?

- How will the difference in airflow between the closed door and open door condition be managed?

- How will the air movement be maintained? If an air velocity is to be achieved, then an air release path will be needed

- Leakage calculations will be required to estimate how much air will be lost from the protected space

- Space available for the equipment

For more information on any of the above topics, please get in touch with one of our technical consultants by emailing info@coltinfo.co.uk or calling us on 02392 451111.

If you would like to receive regular blog updates on industry news, product developments or regulatory changes, sign up to our blog to receive a once-a-month update.

Conor Logan is Associate Technical Director of Colt UK, Smoke and Climate Control Division. Conor designs innovative smoke control and HVAC systems and was Chairman of the Smoke Control Association for over 9 years.

Conor Logan is Associate Technical Director of Colt UK, Smoke and Climate Control Division. Conor designs innovative smoke control and HVAC systems and was Chairman of the Smoke Control Association for over 9 years.